English

Views: 92 Author: www.brightsail-asia.com Publish Time: 2022-04-20 Origin: www.brightsail-asia.com

We often encounter customers who want to establish ginger powder plants.

We have rich project experience and have cooperated with top-level large companies from all over the world, and there are also many successful cases. We would like to share this article with you.

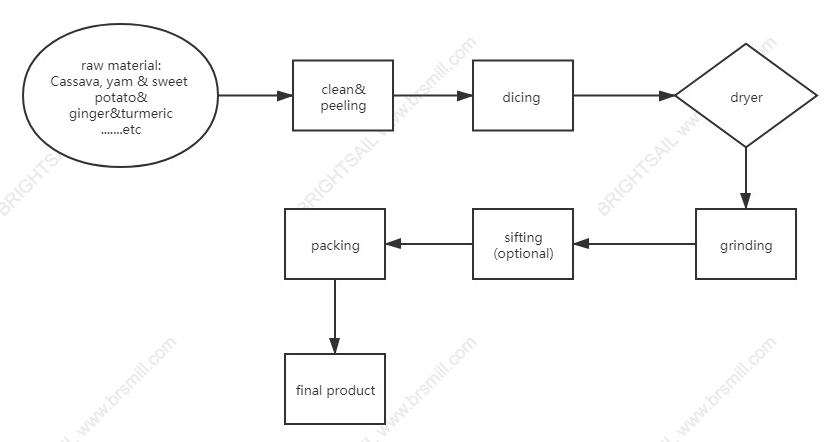

Fresh Ginger → Washing and Peeling → Slicing/Dicing → Drying → Grinding → Sifting → Packing

Ginger powder production process flow chart:

Step 1: Washing and peeling. - Ginger washing machine/Ginger peeling machine

This is BSMG series roller cleaning and peeling machine

It Washs away the mud and dust on the surface of ginger raw materials with running water.

Remove the epidermis of the material.

Step 2: Slicing: vegetable and fruit slicing machine- ginger cutting machine/ginger slicing machine

1)The slicing thickness should be as uniform as possible.

2)Tests and data showed that ginger slices were too thin (less than 1mm), which could shorten the drying time, but the gingerol, the main ingredient in the raw material, was also easily lost.

3)The ginger slice should not be too thick (no more than 4mm), otherwise it will lead to a long drying time for the raw material.

4)Moreover, the internal and external heating of the raw material during drying is significantly non-uniform, which will easily lead to surface hardening and dark color of the dried raw material.

5)The experiment and data show that the thickness of the ginger slices is about 2mm, and the slices should be kept even as far as possible.

Step 3: Drying: - Ginger dryer machine

1)Generally, the drying temperature should be 60-80℃, and the drying time should be based on the water content of ginger slices not more than 12%.

2)Too low drying temperature will lead to longer drying time, resulting in unnecessary biochemical reaction and deterioration of the ginger slice;

3)High drying temperature will result in serious loss of gingerol, the effective component of ginger powder, resulting in low quality of ginger powder.

The dried ginger slices are crushed to 80mesh, 100mesh, 150mesh or 200mesh fine powders.

This ginger grinding machine is very popular.

Sifting (Optional)--sifting machine

Through comparison and comprehensive consideration,60 mesh or 80 mesh of vibrating screen was used to screen the large particles of ginger powder,especially the ginger fiber which could not be crushed.

Fully automatic powder packing machine

Mainly are bottle, rolling film, prefabricated bag or big bag packing.

There are 500g, 1000g, 20kg...etc. It depends on the needs of customers.

We provide the full complete set of ginger equipment described in the above information.

Each customer's process requirements will be a little different,

we will design system solution scheme and give overall quotation for budget reference according to the customer's specific requirements.

Regarding the ginger powder production line, we often do 100kg/h, 500kg/h and 1000kg/h projects.

Actually, we can do 50-2000kg/h ginger powder line.

This depends on the customer's capacity requirement.

Tel: +8615961653782

Fax:+86-510-86389258

Phone: +8615961653782

E-mail: info@brightsail-asia.com

Skype: jewel.qian

Whatsapp:+8615961653782