English

BSPM-A100

Brightsail

| Availability: | |

|---|---|

| Quantity: | |

Product Description

BSPM-A100 powder packing machine can do the work of bag-making, weighting, filling, filling the nitrogen, date coding, and bag-cutting. It is suitable for packing power and granule material such as milk tea, monosodium glutamate, solid beverage, sugar, grape sugar, coffee, feedstuff, solid medicine, powder type additive, and dye, etc.

BSPM-A100 big powder filling machine uses PLC Servo System and pneumatic control system and super touch screen to compose the drive control center,which maximize the whole machine’s control precision ,reliability and intelligentized level.

Advantages

1. Equipped with safety protection, comply with firm’s safety management requirements.

2. Use intelligent temperature controller to have accurate temperature, which ensures the artistic and neat seal.

3. Use PLC Servo System and pneumatic control system and super touch screen to compose the drive control center,which maximize the whole machine’s control precision, reliability and intelligentized level.

4. Touch screen can store the technical parameters of various kinds of products, it is unnecessary to reset while products changing.

5. With error indicating system, which help to handle the trouble immediately.

6. Make pillow bags and hanging bags in terms of customers' different requirements.

Detailed Image

Technical Data

| Model | BSPM-A100 |

| Package weight | 5~50 KG (depending on raw material) |

| Packing accuracy | ≤1‰ |

| packaging speed | 2-4 packs per minute |

| Hopper volume | 150L |

| Total power | 2KW |

| Overall Dimensions | 1000*1000*2300mm |

Big Bag Packing Solution

Packing Process:

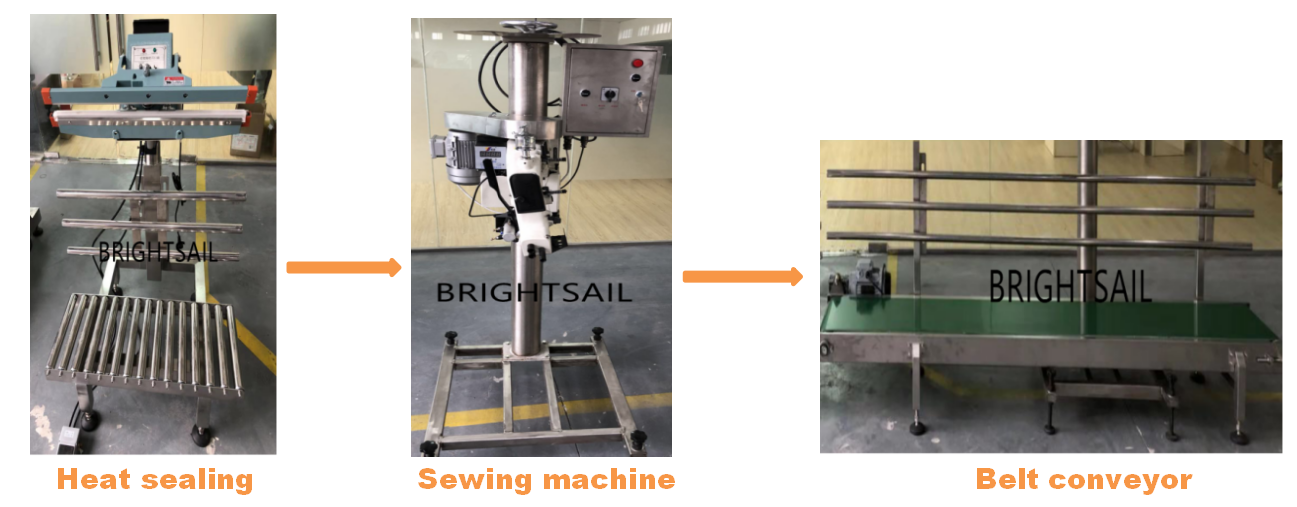

Screw feeder → ultra-fine powder packaging machine (with lifting) → heat sealing machine → sewing machine + conveyor belt.

Brief Description:

1. This bag packaging production line is configured in accordance with national standards, and the entire production process is highly automated and meets Chinese production standards;

2. Introduction of the production line

a. Brief description of machinery and equipment

(1)The appearance and material contact parts of the supporting production line of this production line are made of 304 stainless steel, and all machine structures are selected and designed in accordance with food hygiene standards;

(2)The materials of the containers in contact with the materials are all food-grade SUS304 or food-grade PP materials;

(3)The structures that are frequently dismantled and washed are connected by easy-to-disassemble parts to ensure convenient handling and sanitation when shifting or changing products;

b. This set of production line requires 1-2 employees during normal production.

content is empty!

Tel: +8615961653782

Fax:+86-510-86389258

Phone: +8615961653782

E-mail: info@brightsail-asia.com

Skype: jewel.qian

Whatsapp:+8615961653782