English

Product Application

This machine is a mixing machine which is unique、efficient and with high precision. It uses a set of motor and cycloidal pin gear speed reducer, composing revolution and rotation,making mateials whose ratio with great disparity achieve the ideal mixing degree, short mixing time and good effect. This machine is widely used in medicine、food、chemical industry、pesticide、feed、petroleum、metallurgy mine、building material industry、coating.

Working Method

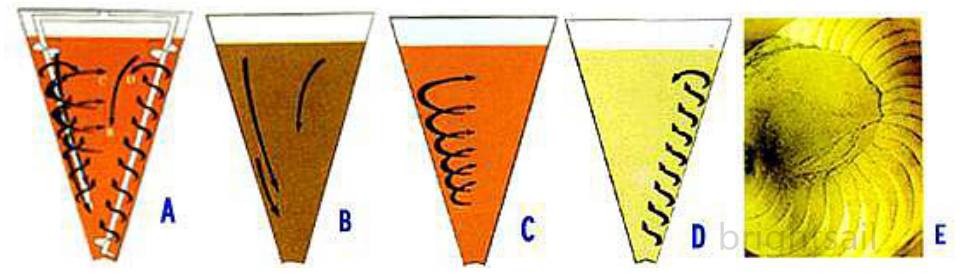

The rotation and revolution of the mixer is controlled by a set of motors and the cycloidal pinwheel reduction. The mixer has the features of quick mixing and wide mill.

These 5 pictures show the method well.

Features

1.This machine has advancement structure, easy operation, safe and reliable working. Because there are no bottom bearings in the screw axis, it eliminated the breakdown that was caused by pulverized-coal leakage of bottom bearings.

2. This machine has fast mixing speed, well-distributed mixing quality. The arrangement of double helix of this machine is asymmetric, expanding the scope of the stirring because of the different size of double helix, thus the comparison is very great, it is very useful to mix materials whose ratio is very special. This machine has short mixing time, high mixing uniformity and clean discharge.

3. The effect of energy saving of this machine is remarkable. When compared with the drum mixer, this machine only consumed 1/10 of energy of the drum mixer.

4. The process of mixing is warm, the material will not pressure-fed, abrade, overheating.

5. The preparations is stable after mixing, it will not layer and isolate.

6. This machine has good sealing, easy operation, convenient maintenance and long service life, making the cone into pressure vessel for compression and vacuum operation according to users’ requirements.

7. Materials can be divided into carbon steel and stainless steel and users can choose as their needs.

Technical Data

| Model | BSD-200 | BSD-500 | BSD-1000 | BSD-2000 | BSD-3000 | BSD-4000 | BSD-10000 | BSD-15000 |

| Total volume (m3) | 0.2 | 0.5 | 1 | 2 | 3 | 4 | 10 | 15 |

| Loading coefficient | 0.6 | 0.6 | 0.6 | 0.6 | 0.6 | 0.6 | 0.6 | 0.6 |

| Max.loading weight(kg) | 95 | 190 | 380 | 720 | 1080 | 1400 | 3600 | 5400 |

| Loosen density | -0.8 | -0.8 | -0.8 | -0.8 | -0.8 | -0.8 | -0.8 | -0.8 |

| Material granularity (mesh) | 20-250 | 20-250 | 20-250 | 20-250 | 20-250 | 20-250 | 20-250 | 20-250 |

| Power(kw) | 2.2 | 4 | 4 | 5.5 | 5.5 | 11 | 18.5 | 22 |

| Mixing time (min) | 6-10 | 8-10 | ||||||

| Overall size(mm) | φ900×1905 | φ1160×2215 | φ1450×2820 | φ1850×3450 | φ1850×3450 | φ2260×4210 | φ3080×5810 | φ3576×6310 |

| Weight(kg) | 500 | 600 | 1300 | 1600 | 1600 | 2800 | 5600 | 6700 |

content is empty!

Tel: +8615961653782

Fax:+86-510-86389258

Phone: +8615961653782

E-mail: info@brightsail-asia.com

Skype: jewel.qian

Whatsapp:+8615961653782