ZKS Series Pneumatic Vacuum Feeding Machine

Turmeric Powder Making Machine

Automatic Powder Packing Machine System

Red Chilli Grinding Machine

Icing Sugar Machine

Air Classifying Mill Price

QVC Series Pneumatic Vacuum Feeding Machine

Thermoplastic Powder Coatings

BSXR Falling Type Metal Detector

BS Carob Seeds Remove Machine

BSST Series High Efficient Sifting Machine

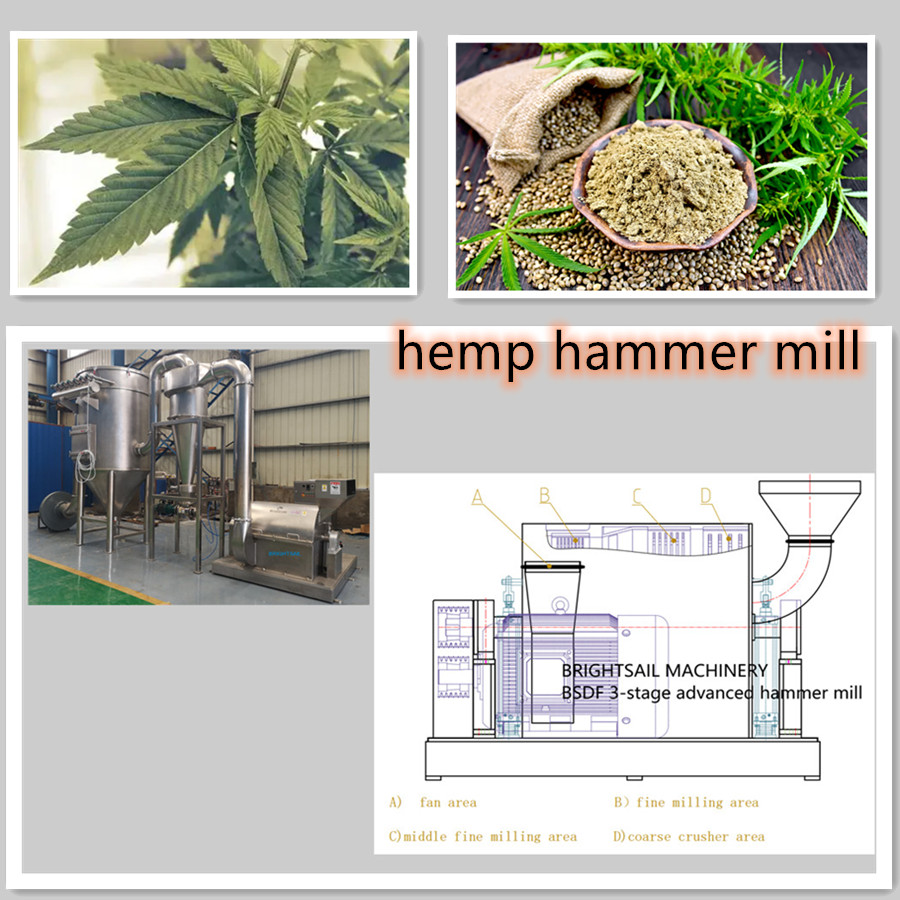

Hemp Grinder