Sri Lanka Chili Grinding Machine

BS Conveyor Belt

BSG Dust Collecting Grinding Unit

BS Series Small Hammer Mill

BSPM-A100 Big Bag Packer For Powder

BSL Double Shaft Mixer

Herbal Fine Powder Grinding Machine

Food Grinding Machine for Ginger

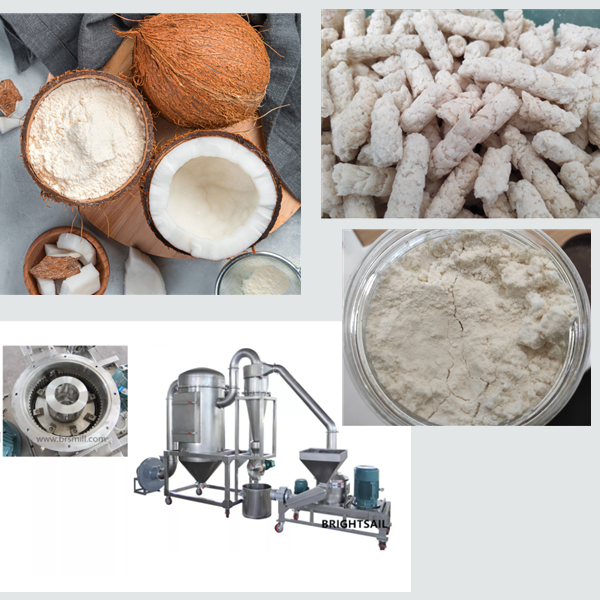

Coconut Powder Making Machine

Rice Flour Mill

Icing Sugar Machine

BSPM-F Sachet Automatic Powder Packing Machine