Turmeric Grinding Machine

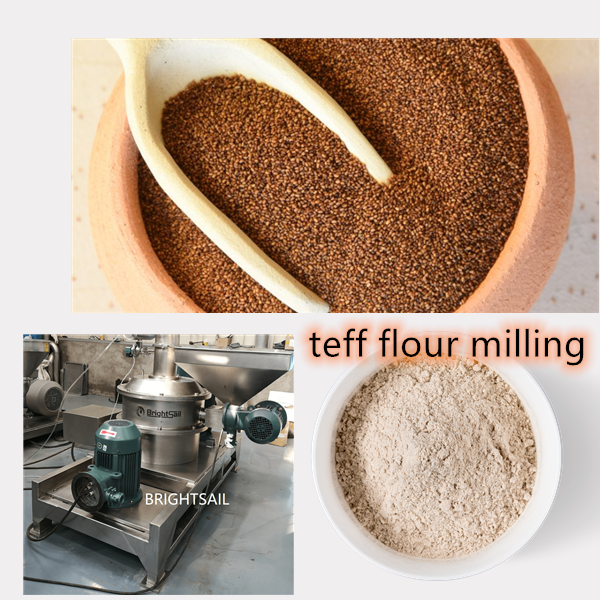

Teff Flour Milling Machine

BSWD Conical Rotating Vacuum Dryer

Sri Lanka Chili Grinding Machine

BS-6D Tea Bag Packing Machine

Chilli Grinding Machine

Seeds Grinding Machine

BSQP Double Head Vegetable Cutting Machine

Turmeric Powder Making Machine

BS-NW160 Tea Bag Packing Machine

Liquorice Grinding Machine

BSPM-B100 Big Bag Packer For Superfine Powder