As a result of ours specialty and service consciousness, our company has won a good reputation among customers all over the world for air classifying mill coating plant suppliers,

flour mill grinder machine, We welcome new and old customers from all walks of life to contact us for future business relationships and achieving mutual success!, moldova, We are committed to meet all your needs and solve any technical problems you may encounter with your industrial components. Our exceptional products and vast knowledge of technology makes us the preferred choice for our customers. 1. Conveyor machines for conveying raw materials into the other machine (flour conveyor)

how to make a spice factory? you will need spice cleaning machine, spice dryer machine spice roaster, spice powder crush

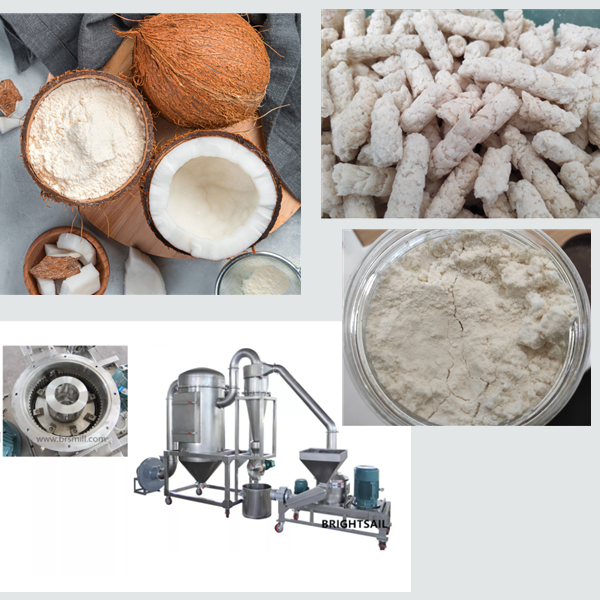

Today is a busy day, the BSP-350 superfine pulverizer is loaded into the container and will be used for the grinding of

Type 1: BSP Air Classifier Mill(superfine powder leaf pulverizer machine)BSP Air Classifier Mill, its another name is Ai