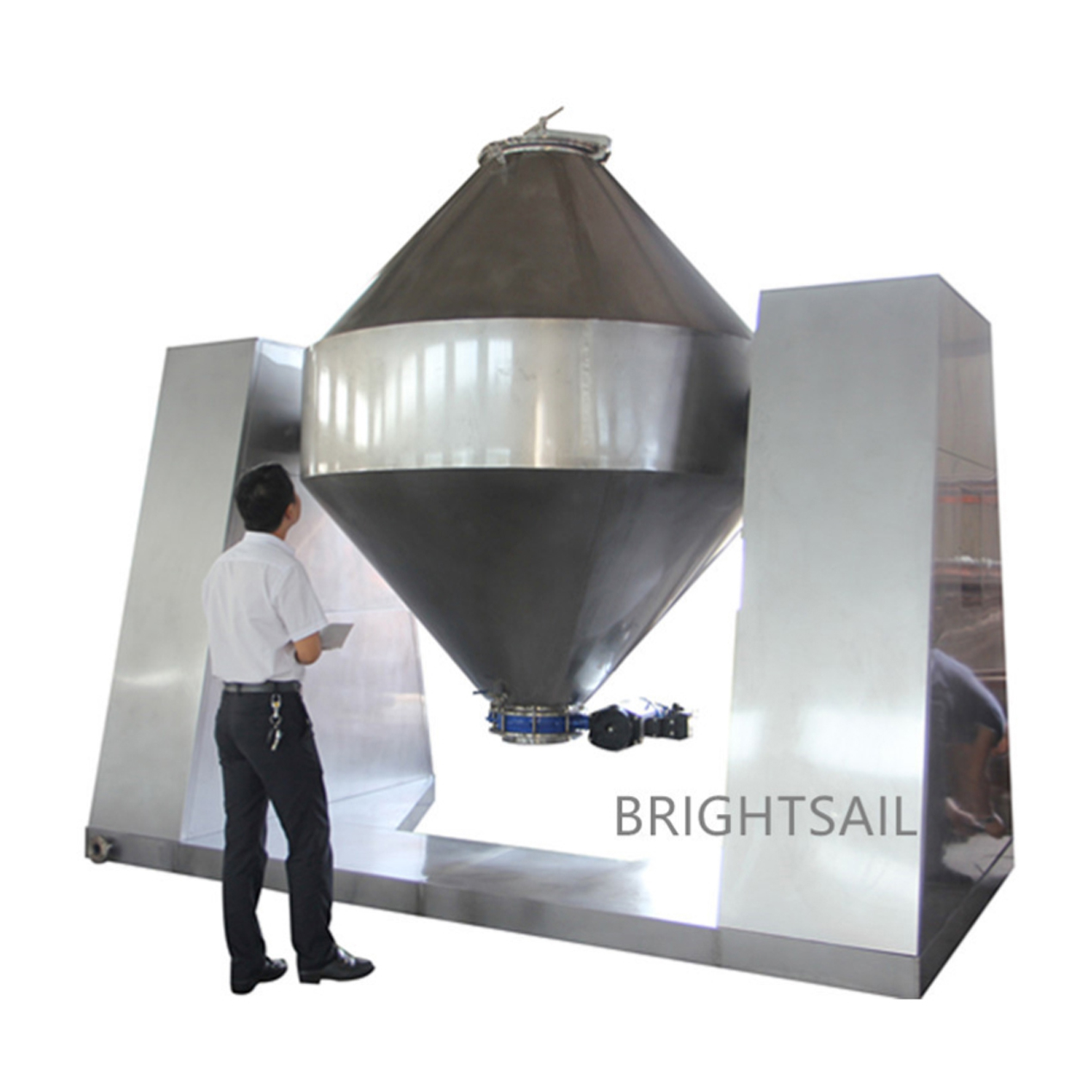

BSVD Square Vacuum Dryer

Herb Grinding Machine

BSNJ Garlic Mash Machine

Turmeric Grinding Machine

Small Chili Powder Making Machine

BSF high efficient hammer mill

BSDF Series Dust-free Feeding Hopper

Grinder for seeds and nuts

Ginger Powder Machine

BS-C12 Tea Bag Packing Machine

Rice Flour Mill

Polymer Synthetic Material Powder Additive