We also offer product sourcing and flight consolidation services. We have our own factory and sourcing office. We can provide you with almost every type of product related to our product range for dry spice grinder machine,

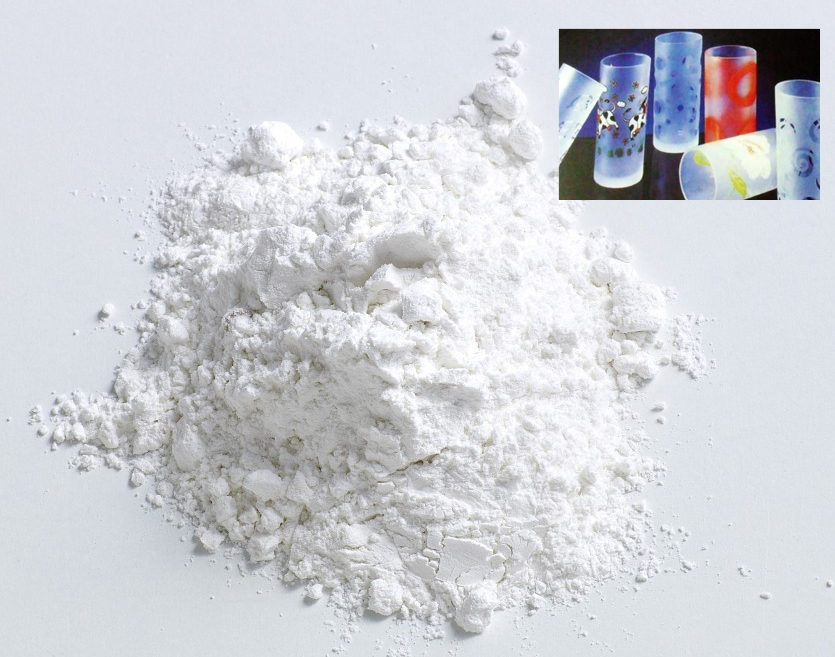

coffee grinder spice mill,hammer mill grinder for sale,To achieve reciprocal advantages, our company is widely boosting our tactics of globalization in terms of communication with overseas customers, fast delivery, the best quality and long-term cooperation. The product will supply to all over the world, such as Europe, America, Australia,Kenya, South Korea,Malaysia, Mexico.We aspire to meet the demands of our customers globally. Our range of merchandise and services is continuously expanding to meet customers' requirements. We welcome new and old customers from all walks of life to contact us for future business relationships and achieving mutual success Chickpeas flour is very common food in many countries, many customers have a demand to make this product. The chickpeas

Last week, one more set of our BSDF-750 chilli grinding machine had been finished. It’s for our client in Thailand to gr

How to make ginger powder? We often encounter customers who want to establish ginger powder plants. We have rich project

Our BS-630 hammer mill is being checked,it will be sent out days later.Our BS hammer mill is specially suitable for

BSG flour mill is connected with cold air machine,it can grind hogh oil content materials.It is good at grinding pepper,