English

BSPM-B100

Brightsail

| Availability: | |

|---|---|

| Quantity: | |

Introduction

The packaging machine is designed in accordance with national GMP standards, and is mainly developed and designed for ultra-fine powder that is easy to dust and high-precision packaging requirements. According to the signal given by the weight sensor installed under the container, it completes two-speed filling, metering, and lifting. It is suitable for packaging additives, carbon powder, dry fire extinguisher powder, other ultra-fine powders, and powders with high-precision packaging requirements.

The main body of this machine is made of 304 stainless steel, and the motor, cylinder, electrical accessories, pneumatic components, etc. are all selected well-known brands, or customers can specify brands.

Features

1. A weight sensor is installed under the container tray, fast and slow filling according to the preset weight to ensure high packaging accuracy.

2. Servo motor drives the tray up and down, the lifting speed can be set arbitrarily, and basically no dust is raised to pollute the environment during filling.

3. Servo motor and servo drive control screw, stable performance and high precision.

4. PLC control, touch screen man-machine interface display, easy to operate.

5. All stainless steel structure; combined material box, easy to clean.

6. The filling head is equipped with an adjustable height device, which can easily achieve a variety of specifications for packaging.

7. The fixed screw installation structure will not affect the material properties during filling.

8. Work flow: manual bagging or canning → container raising → fast filling, while the container drops → weight reaches the preset value → slow filling → weight reaches the target value → stop → manually take out the container.

9. Pneumatic bag clamping device and can holding device are available for selection, just choose different devices to meet the requirements of canning and bagging.

Techniclal Data

| Model | BSPM-B100 |

| Packing weight | 5-50kg (depending on raw material) |

| Packaging Accuracy | 5-20Kg,≤±0.1-0.2%; ≥20Kg,≤±0.05-0.1% |

| Packaging speed | 2-4 bags per minute |

| Power supply | 3P AC380V 50Hz |

| Total power | 3.3KW |

| Total weight | 450KG |

| Material box volume | 100L |

| Boundary dimension | 800mm*1200mm*3200mm |

| Air source | 0.6-0.8Mpa(The air compressor is provided by the customer) |

Big Bag Packing Solution

Packing Process:

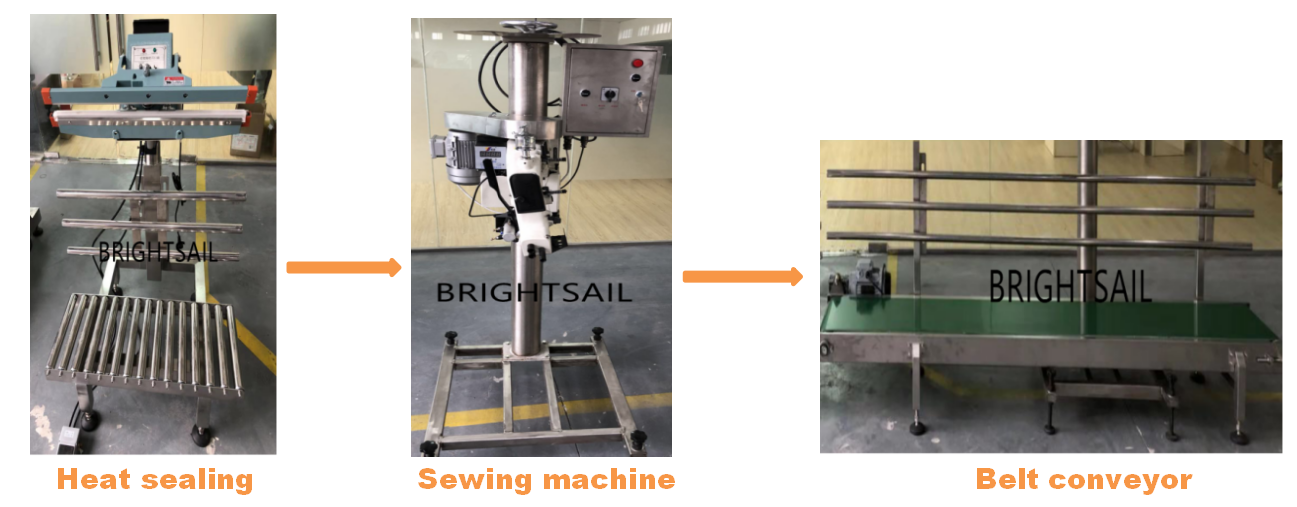

Screw feeder → ultra-fine powder packaging machine (with lifting) → heat sealing machine → sewing machine + conveyor belt.

Brief Description:

1. This bag packaging production line is configured in accordance with national standards, and the entire production process is highly automated and meets Chinese production standards;

2. Introduction of the production line

a. Brief description of machinery and equipment

(1)The appearance and material contact parts of the supporting production line of this production line are made of 304 stainless steel, and all machine structures are selected and designed in accordance with food hygiene standards;

(2)The materials of the containers in contact with the materials are all food-grade SUS304 or food-grade PP materials;

(3)The structures that are frequently dismantled and washed are connected by easy-to-disassemble parts to ensure convenient handling and sanitation when shifting or changing products;

b. This set of production line requires 1-2 employees during normal production.

content is empty!

Tel: +8615961653782

Fax:+86-510-86389258

Phone: +8615961653782

E-mail: info@brightsail-asia.com

Skype: jewel.qian

Whatsapp:+8615961653782